Levo

An adjustable, counterbalancing monitor arm for use with any screen or laptop.

Client

Year

Brief

2017 - 2019

Metalicon (Arrow Group)

Develop a mechanically counterbalancing arm to hold up to two computer monitors or laptops. The successful solutions needed to:

Carry between 2 – 10kg of weight from one or two computer monitors.

Have adjustable counterbalanced height adjustment.

Provide three rotational axes of movement to position a screen around a desk.

Offer further tilt and twist axes to rotate and angle screens.

Outcome

Developed from initial concept, through extensive prototyping, into manufacture. Conceived patented features and were responsible for complete production engineering.

The Levo monitor arm has been successfully selling since its launch in 2019. It’s success has made the other similar products within the Levo portfolio obsolete. It has received great customer response and is consistently displayed as the hero product among Metalicon’s large catalogue.

Key Design Features

Tool-free installation and adjustment with built-in Hex key storage.

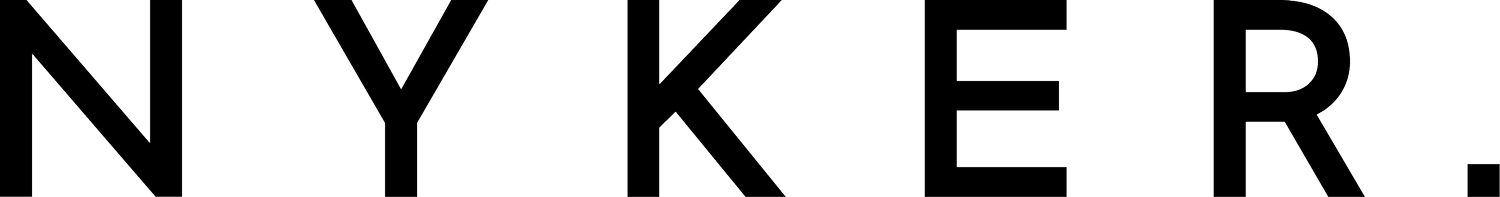

Optional dual screen rail for mounting two computer monitors.

Optional laptop holder to replace any monitor.

Effective cable management for an uncluttered installation.

Multiple mounting options for a variety of office environments.

“Nyker’s designs were easy to assemble and adjust, enabling the company to patent more features. The team communicated well, ensuring a seamless collaboration. Above all, they were brilliant in solving any project issues.”

Calvin Temple, Product Manager - Arrow Group

Generating Novel Features to Obtain Patents

Throughout development introduced a wide array of innovative features and mechanisms. These have greatly added to the value of the device - from the built-in tool storage to the innovative tilt adjustment head. Many features conceived by Nyker have gone on to form the cornerstone of utility and design patents. This has helped Metalicon to differentiate their product range from the competition and gain a strong foothold in the market.

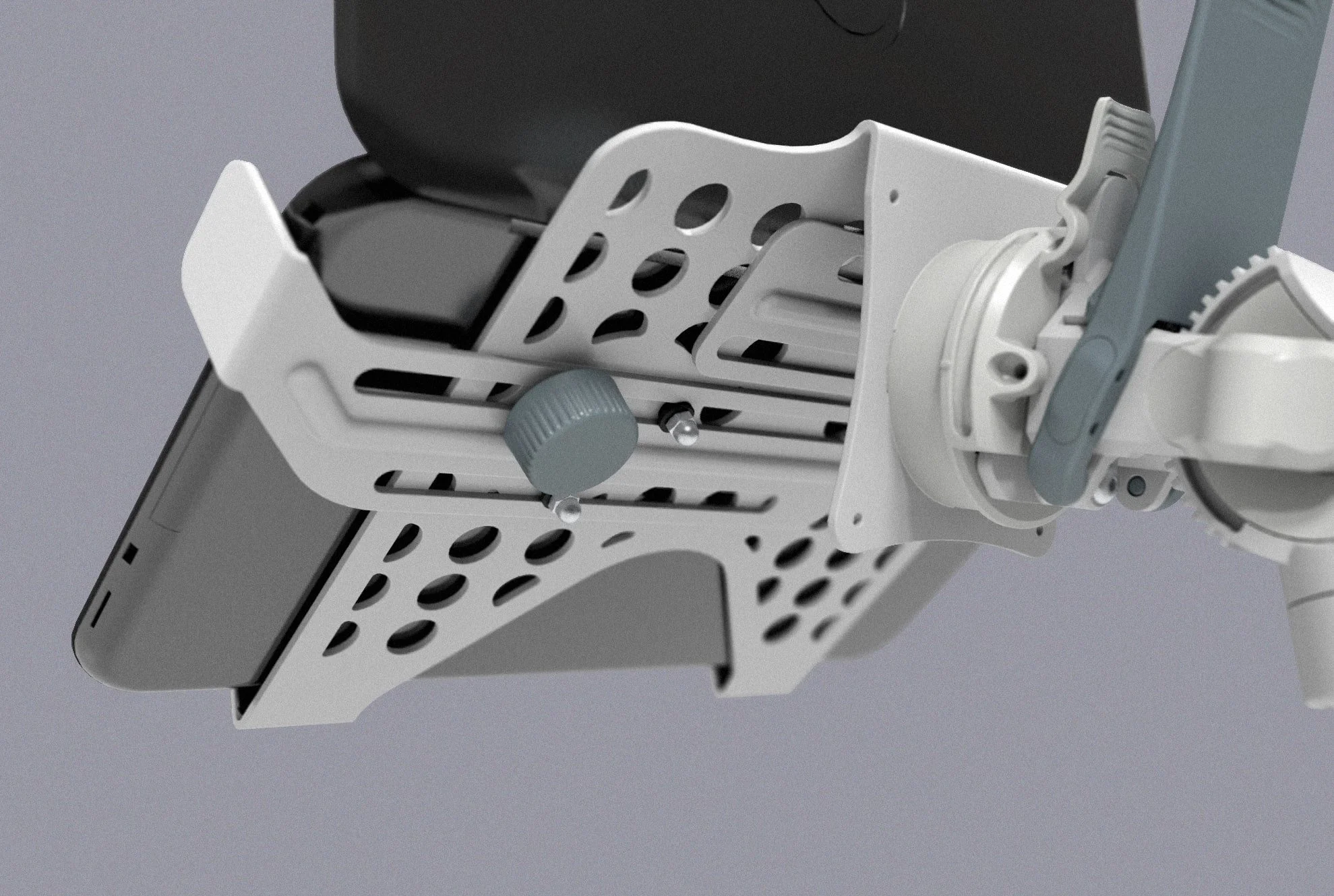

Prototyping Complex Mechanics

Built from over 200 components comprising 73 unique parts, there were numerous intricate mechanisms which needed to work reliably to deliver a high-quality final product. In the course of development, we produced numerous functional prototypes to test specific features and the complete assembly.

The innovative geared head went through several iterations of prototypes from rapid plastic 3D prints to full metal models which represented final strength. This strategy was applied to many other mechanisms in the arm which resulted in a production model with considered and reliable movements.

Complete Design for Manufacture

Levo marries a wide number of manufacturing processes from die casting and injection moulding to extrusion and metal stamping. Each component has been meticulously engineered to account for the requirements and limitations of their own process. All manufacture ready files were made and communicated to manufacturers by our team.

We worked directly with an original equipment manufacturer (OEM) to supply the complete product. Over the course of six production samples we analysed, modified, and re-communicated the design to the supplier to overcome manufacturing limitations and faults.

Plastic Free Packaging

We were tasked by Metalicon to package Levo without single-use plastics. We went about developing several card pulp moulded parts which balanced cost and aesthetics without having a detrimental impact on the environment.

We strive to improve the sustainability of all products we develop, and eliminating single-use plastic packaging one step towards lowering the impact of new innovations.